Application of Frequency Converter in Glass Tempering Furnace

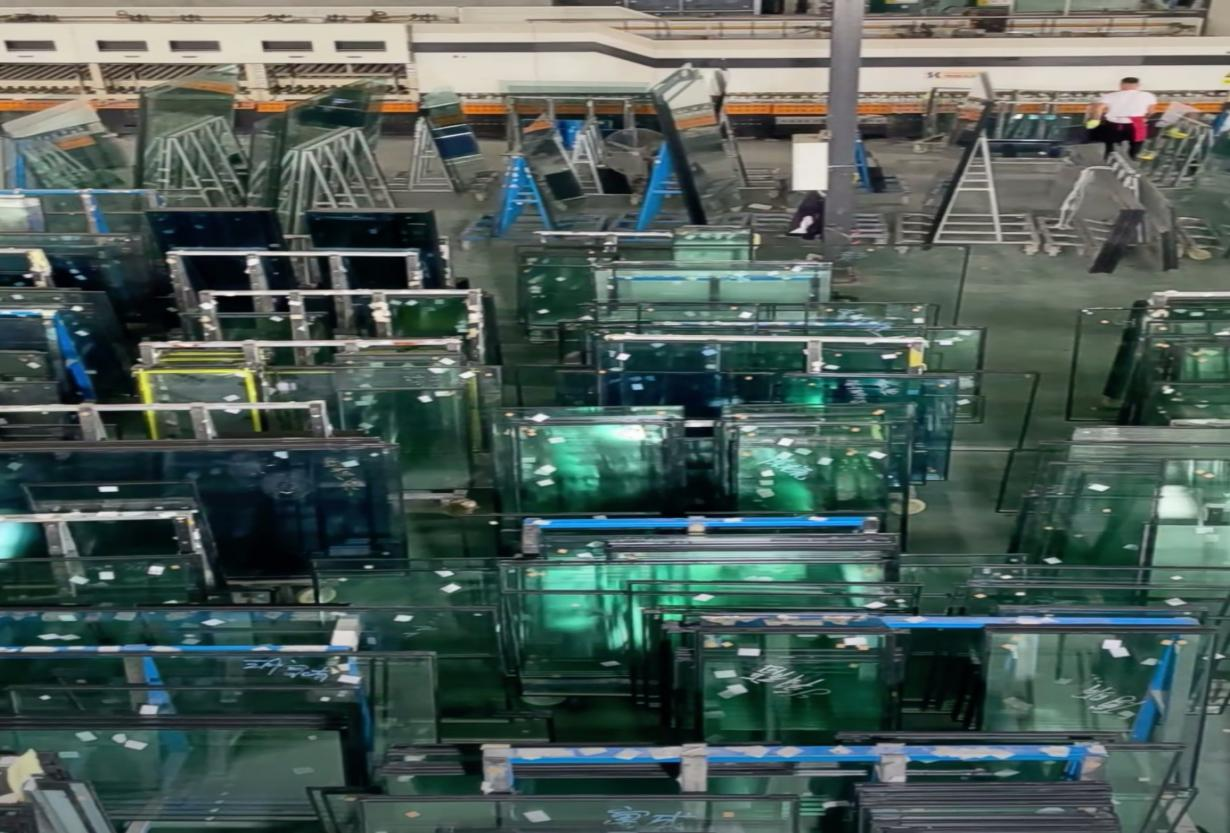

Glass is one of the materials we frequently see and use in our daily lives. With a long history and a wide range of applications, glass has gradually developed unique functions with the advancement of modern technology, giving rise to products with superior performance, such as tempered glass. When talking about tempered glass, it is essential to discuss the glass tempering furnace (shown in the figure below) and its working principle.

Structure of Glass Tempering Furnace:

The glass tempering furnace unit is mainly composed of the loading section, convection heating section, flat tempering section, and unloading section, as well as a high-pressure centrifugal fan, air supply duct, wind collecting box, air path, electrical control cabinet, operating console, etc. The transmission of various parts of the unit adopts AC frequency conversion technology, driven by electric motors with adjustable reciprocating drive speed. The operation of each part is automatically completed by a control system composed of an industrial computer and PLC. The high-pressure centrifugal fan generally consists of two motors (355KW and 132KW) driven by motors (depending on the size and model of the tempering furnace), with our company's frequency converters, 355KW and 132KW each. Typically, during standby, it runs at low frequency, and during cooling, it runs at high frequency, providing the system with stable and continuous high-pressure air. The quality of tempered glass depends on the control of air volume and temperature.

Key Parameters of the Frequency Converter: F0.02=1, F0.03=3, F0.17, F0.18 depend on the power, F1 group motor self-identification, F2.20=2.20.

Glass Tempering Process:

Tempered glass is a kind of prestressed glass. After cutting ordinary glass into the required size, it is conveyed by the first-stage roller to the second-stage roller for heating. After heating in the furnace to nearly 700°C, close to softening, it is then conveyed to the third-stage roller for rapid and uniform air cooling. At this point, our frequency converter will run at a high frequency, allowing the high-pressure centrifugal fan to output sufficient air volume to rapidly cool the glass. Afterward, it is conveyed out through the fourth-stage roller to complete the tempering of the glass, obtaining tempered glass.

Advantages and Applications of Tempered Glass:

Tempered glass has the advantages of high strength, high temperature resistance, relatively uniform granular fracture when broken, and relatively small harm. In contrast, ordinary glass fractures into sharp-edged pieces, posing greater risks. Tempered glass is commonly used in various fields such as automobiles, lamp protection, construction, interior and exterior decoration, commercial counters, display windows, and more.

Quanzhou Ausenist Technology Co., Ltd

Quanzhou Ausenist Technology Co., Ltd