Process Introduction

The printing machine is driven by the main motor through belt drive, gear transmission, and chain drive, enabling the coordinated mechanical connection and action among various rollers, toothed racks, and mechanisms. Controlling the main motor means controlling the overall operation of the machine. In old-fashioned printing machines, the main motor adopts electromagnetic speed regulation, resulting in high power consumption. Additionally, the transmission part of the motor generates significant heat, requiring the addition of a cooling device in summer, further increasing power consumption.

The speed control of the main motor in old-fashioned printing machines involves two processes. Firstly, there is the initial adjustment for low speed used during printing, which the operator can freely adjust. Secondly, after adjustment, there is a fixed-speed printing process, with a speed set during debugging that the operator cannot change. Additionally, the old-fashioned printing machine is equipped with a low-power low-speed motor for forward inching and reverse inching.

According to the process requirements, the variable frequency drive (VFD) transformation plan is as follows:

Remove the original electromagnetic speed control device while retaining the original main motor and clutch. Remove the original low-speed motor. Connect the main motor directly to the main shaft and the entire machine structure.

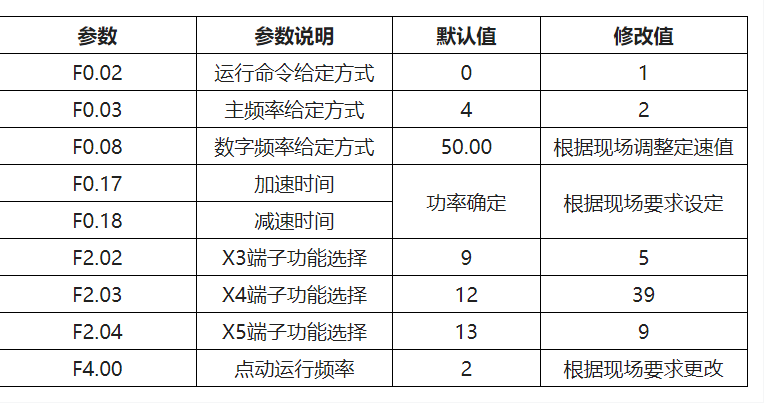

Install our company's 500 series VFD as the motor drive device. Wire and configure the parameters of the VFD as follows:

F0.02: Running command given method (Default: 0, Modified: 1)

F0.03: Main frequency given method (Default: 4, Modified: 2)

F0.08: Digital frequency given method (Default: 50.00, Modify according to on-site adjustment)

F0.17: Acceleration time (Power determined, Set according to on-site requirements)

F0.18: Deceleration time

F2.02: X3 terminal function selection (Default: 9, Modified: 5)

F2.03: X4 terminal function selection (Default: 12, Modified: 39)

F2.04: X5 terminal function selection (Default: 13, Modified: 9)

F4.00: Inch run frequency (Default: 2, Modify according to on-site requirements)

Parameters:

Replacing the original transmission system with a VFD-driven system fully meets the requirements of the old-fashioned printing machine's process, and the transformation process is simple and cost-effective. The adjustment through the VFD is also more energy-efficient and environmentally friendly, and the various protections of the VFD can extend the motor's service life.

Quanzhou Ausenist Technology Co., Ltd

Quanzhou Ausenist Technology Co., Ltd