Features:

AU400 series:(220V input--380V output, 1.5KW-75KW )

AU400 series 220V to 380V frequency converters are specially developed by us for occasions where three-phase power is lacking. With multiple protection methods and excellent driving performance, they can solve the difficulty of users lacking 380V power. The wiring connecting is simple and easy to understand, and the operation is convenient and practical.

Technical Specification

---Universal frequency converter, covering more than 90% applications

---Perfect software and hardware protection function. The output frequency can reach to 500Hz, solved the traditional gear limit problem.

---Powerful current vector control performance, low noise,excellent energy-saving effect

---Speed tracking, Instantaneous stop, 0.1S acceleration and deceleration, 22G and below are with built-in brake unit

---47 kinds of fault detection protection are set to effectively ensure the stable and reliable operation of the system.

---Extensive expansion card options

---Powerful and supports multiple field buses

---Support asynchronous motor control

--- Support user programmable control card (PLC card),and the programming method is fully compatible with H1U series PLC

Applications: numerical control machine, Forging Machine,

Item | Technical Index | Specification |

Input | Input voltage | 3AC 380~460V±15% |

Input frequency | 50/60Hz±5% | |

Output | Output voltage | 0~rated input voltage |

Output frequency | V/f control: 0~500Hz Vector control: 0~2000Hz | |

Control Features | Control mode | V/f control Sensorless vector control (SVC) Close-loop vector control (FVC) |

Operation command mode | Keypad control Terminal control Serial communication control (Modbus) | |

Frequency setting mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined & switched in various modes. | |

Overload capacity | G model: 150%/60s, 180%/3s P model: 120%/60s, 150%/3s | |

Starting torque | 0.25Hz/150% (SVC); 0.5Hz/150% (V/f), 0Hz/180% (FVC) | |

Speed control precision | ±0.5% (SVC) | |

Carrier frequency | 0.5~16.0kHz, automatically adjusted according to temperature and load characteristics | |

Frequency accuracy | Digital setting: 0.01Hz Analog setting: maximum frequency ×0.025% | |

Torque boost | Automatically torque boost; manually torque boost: 0.1%~30.0% | |

V/f curve | Three types: linear, multiple point and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | |

Acceleration/deceleration mode | Straight line/S curve; four kinds of acceleration/deceleration time, range: 0.1s~6500.0s | |

Braking unit | 1.5~22kW: standard build-in. 30~37kW optional for build-in >37kW, external braking unit.. | |

DC braking | DC braking when starting and stopping DC braking frequency: 0.0Hz~maximum frequency, braking time: 0.0s~25.0s | |

Jog operation | Jog operation frequency: 0.0Hz~maximum frequency Jog acceleration/deceleration time: 0.1s~6500.0s | |

Simple PLC & multi-step speed operation | It can realize a maximum of 16 multi-step speeds running via the built-in PLC or control terminal. | |

Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | |

Automatic voltage regulation | Keep output voltage constant automatically when input voltage fluctuating | |

Control Function | Torque limit | “Rooter” characteristics, limit the torque automatically and prevent frequent over-current tripping during the running process |

Wobble frequency control | Multiple triangular-wave frequency control, special for textile | |

Timing/length/ counting control | Timing/length/counting control function | |

Over-voltage & over-current stall control | Limit current & voltage automatically during the running process, prevent frequent over-current & over-voltage tripping | |

Fault protection function | Comprehensive protections include over-current, over-voltage, under-voltage, overheating, default phase, overload, shortcut, etc., can record the detailed running status during failure & has fault automatic reset function | |

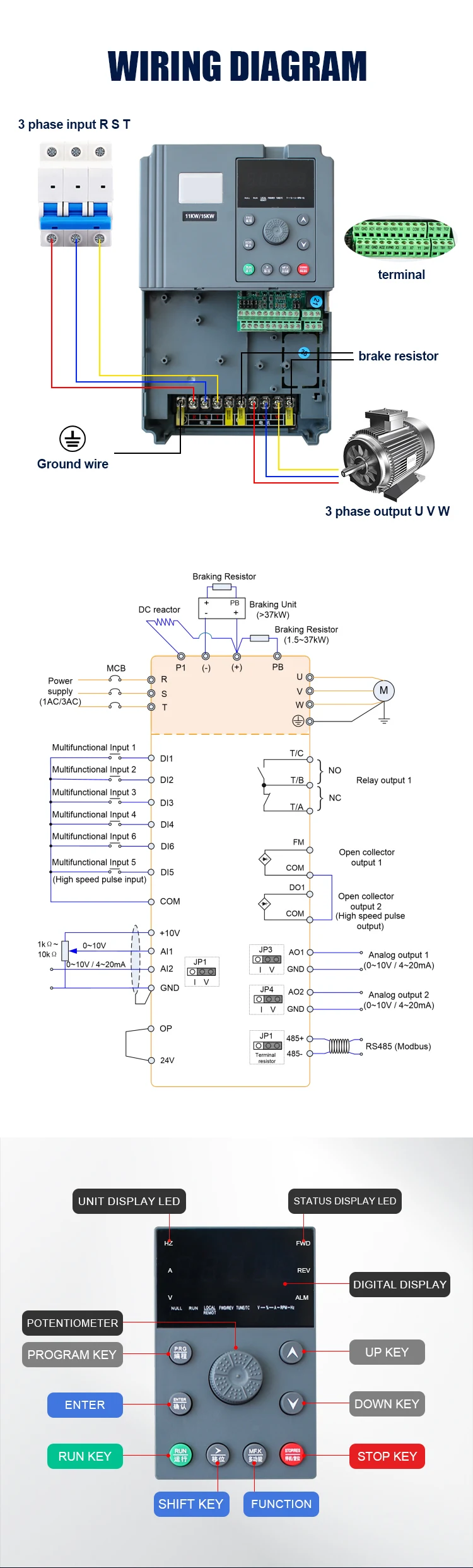

Input/output terminals | Input terminals | Programmable digital inputs: DI1~DI6, DI5 can be used as high speed pulse input terminal. Programmable analog inputs: AI1(0~10V), AI2(compile with both 0~10V & 4~20mA). |

Output terminals | Programmable digital outputs: 1 relay outputs (another 1 can be extended) 2 open-collector outputs, FM can be set as high speed pulse output terminal. Programmable analog outputs: AO1, AO2: compile with both 0~10V & 4~20mA. | |

Communication terminals | Standard RS485 communication interface, support MODBUS-RTU communication protocol | |

Human machine interface | LED display | Display frequency setting, output frequency, output voltage, output current, etc. Two lines display |

Multi-function key | MF.K key, can be used as multi-function key | |

Environ-ment | Ambient temperature | -10℃~40℃ (>40℃, output derated), without direct sunshine. |

Humidity | 90%RH or less (non-condensing) | |

Altitude | ≤1000M: output rated power, >1000M: output derated | |

Storage temperature | -20℃~60℃ |

Quanzhou Ausenist Technology Co., Ltd

Quanzhou Ausenist Technology Co., Ltd