Waterproof and dustproof inverter

| The difference between a normal inverter and a fully sealed waterproof inverter in poor environments | ||

| Comparative items | Normal inverter | Sealed waterproof inverter |

| IP Class | Usually IP20 | IP65 |

| Working life | Poor environment generally 2-3 months | 3-5 years in a poor environment is not a problem |

| Installation method | Poor environment must be installed in a cabinet | Can be installed in the cabinet or exposed |

| Working environment | Suitable for cleaner and drier applications | Suitable for poor environments |

| Replacement frequency | Poor environment replaced more than three times a year | Poor environment replaced once every 3-5 years |

1. Fully enclosed one-piece moulded housing, no gaps at the corners, can be open air or installed in a cabinet

2. High performance vector software, high low frequency torque

3. Infineon modules and other imported components to ensure product stability

4. independent heat dissipation structure, internal circuit board and external environment isolation

5. Specially for harsh environment places, extend the service life

6. Water-proof, dust-proof and iron-proof, moisture-proof, corrosive gas-proof and oil-proof

7. Imported high-powered waterproof fan, fast heat dissipation and strong durability

8. Control mode switch freely

9. Imported three-proof paint on the circuit board

10. 11 big protection, reduce motor damage

Industry application: grinding machines, CNC machine tools, chemical plants, printing and dyeing plants, moisture anti -corrosion and anti -corrosion, saline -alkali land, graphite processing, stone processing, food processing, sewage pumps, limestone plants, feed factories and other areas, humidity, corrosion, powder and other areas.

Item | Specifications | ||

Basic function | Control system | High performance of current vector control technology to realize | |

Drive performance | High efficiency driving for induction motor | ||

Maximum frequency | 0~500Hz | ||

Carrier frequency | 0.8k~8kHz;the carrier frequency will be automatically adjusted | ||

Input frequency resolution | Digital setting: 0.01Hz | ||

Control mode | Open loop vector control(SVC) | ||

Startuptorque | Type G: 0.5Hz/150%(SVC); 0Hz/180%(FVC) | ||

Speed range | 1: 100(SVC) | Speed range | |

Speed stabilizing precision | ±0.5%(SVC) | Speed stabilizing precision | |

Torque control precision | ±5%(FVC) | ||

Over load capability | G type: rated current 150% -1 minute, rated current 180% -3 seconds; | ||

Torque boost | Auto torque boost function; Manual torque boost 0.1%~30.0% | ||

V/Fcurve | Linear V/F,Multi-point V/Fand Square | ||

V/F separation | In 2 ways: separation ,semi seperation | ||

Acc. /deccurve | Straight line or S curve acceleration and deceleration mode. | ||

DC brake | DC brake frequency : 0.00Hz to maximum frequency,brake time : | ||

Jog control | Jog frequency range: 0.00Hz~50.00Hz. Jog | ||

Simple PLC and MS speed | It canrealize atmaximumof 16 segments speedrunning via the built-in PLC or control terminal. | ||

Built-in PID | It is easy to realize process-controlled close loop control system | ||

Auto voltage regulation | Itcankeepconstantoutputvoltageautomaticallyincaseof change ofnetworkvoltage. | ||

Over-voltage/current stall | Itcanlimittherunning | ||

Quick current limit | Minimizetheover-currentfault,protectnormaloperation of the inverter | ||

Torque limit & control | "Excavators" characteristics,automatically limit torque during operation,prevent frequent over-current trip; | ||

Personalized | Instantaneous stop | When instantaneous power off,voltage reduction is compensated through load feedback energy,which could make inverter keep running in a short period of time. | |

Rapid current limit | To avoid inverter frequent over-current fault. | ||

Virtual IO | 5 groups of virtual DI,DO to realize simple logic control | ||

Timing control | Timing control function: set time range 0 Min~6500.0 Min | ||

Multiple motor switch | 2 groups of motor parameter,which can realize 2-motor switch control | ||

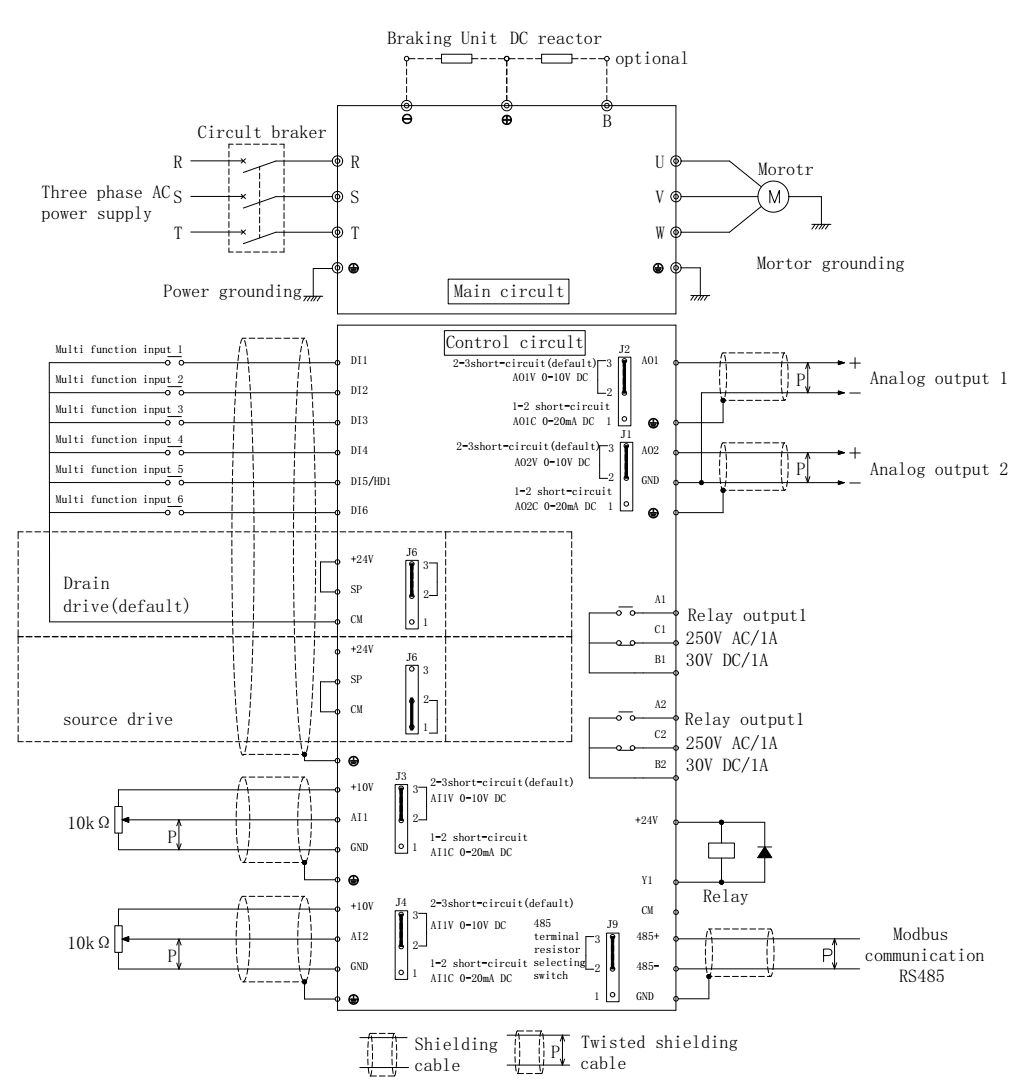

Multi-threaded bus support | Support 3 kinds of field bus: RS485, Profibus-DP, CAN open | ||

Motor overheat protection | Select optional TZ5PC1 analog input AI3x can accept the motor | ||

Multi-encoder support | Support difference,open collector, rotary transforme etc. | ||

Programmable PLC | Select optional user programmable card,which can realize secondary | ||

Excellent backend software | Support inverter parameter operation and virtual oscilloscope function.Inverter internal state graphic monitor can be realized through virtual oscilloscope. | ||

Running | Running command channel | Three types of channels: operation panel reference,control terminal | |

Frequency source | There are totally eleven types of frequency sources, such as digital | ||

Auxiliary frequency source | 11 kinds of auxiliary frequency source which can flexible achieve | ||

Input terminal | Standard: | ||

Keyboard operation | LED display | Realize parameter setting,status monitoring function | |

Keyboard potentiometer | Equipped with keyboard potentiometer or coding potentiometer | ||

Key lock&function selection | Realize button locking,define operation range for part of buttons to | ||

Protection function | Itcanimplementpower-onmotor short-circuit | ||

Environment | Using place | Indoor,andbefreefromdirectsunlight,dust,corrosivegas, combustible | |

Altitude | Below 1000m | ||

Ambient temperature | -10 ºC to +40 ºC (Derating use when under ambient temperature of | ||

Humidity | Less than 95%RH, without condensing | ||

Vibration | Less than 5.9 m/s2(0.6g) | ||

Storage temperature | -20ºC~+60ºC | ||

Quanzhou Ausenist Technology Co., Ltd

Quanzhou Ausenist Technology Co., Ltd